Materials We Offer

We offer a range of materials with fast lead times – should a project require something specialised we have the capacity to work with you to get the job done. Reach out to us to discuss further options!

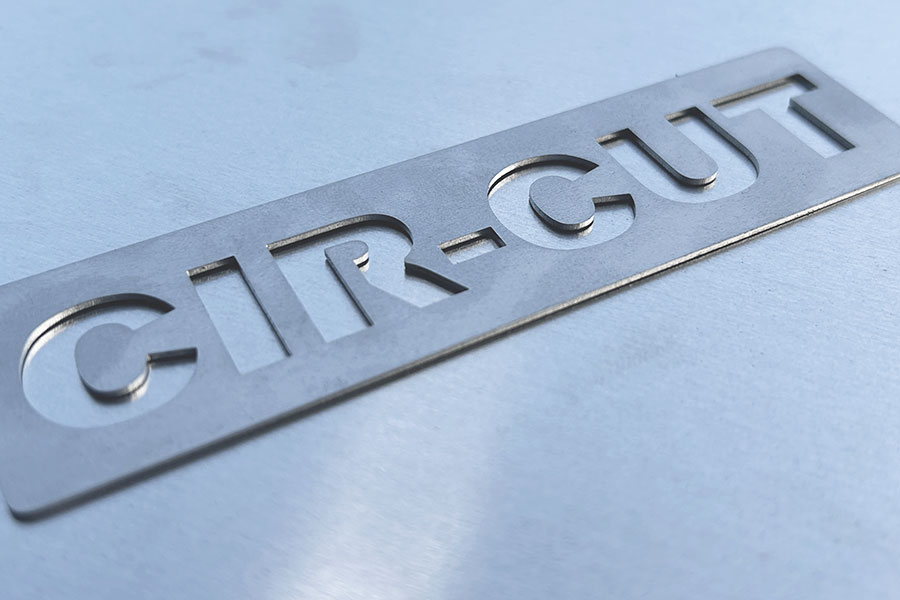

Aluminium (5052)

- 2mm

- 3mm

- 4mm

- 5mm

Aluminum 5052 is a widely used alloy known for its excellent corrosion resistance and good strength-to-weight ratio. It offers superior workability and machinability to most other aluminium alloys, making it ideal for forming and welding. Common applications range from marine equipment and fuel tanks to automotive panels and components due to its durability in harsh environments.

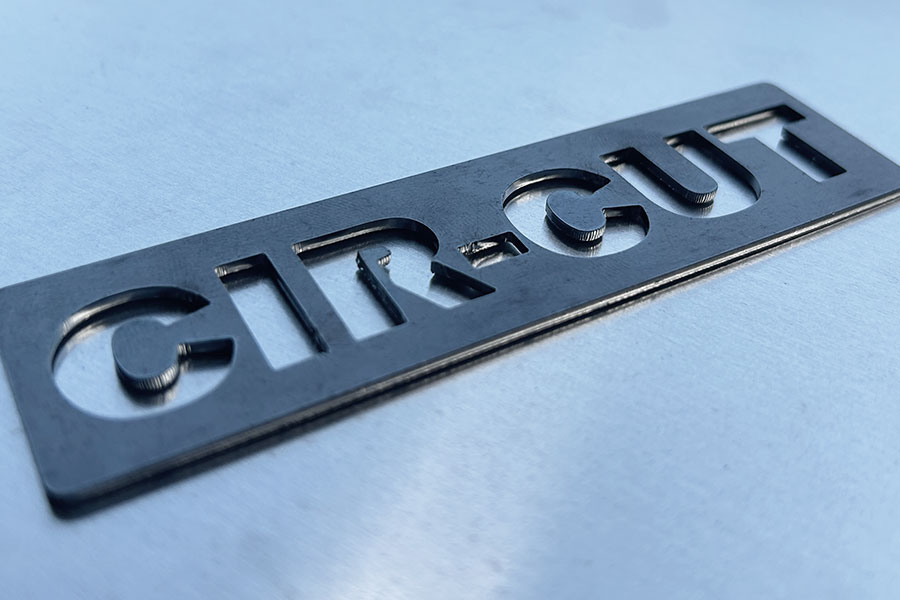

Mild Steel (AISI 1020/A36)

- 1.6mm

- 3mm

- 5mm

- 6mm

- 10mm

- 12mm

A36 mild steel is one of the most popular low-carbon steels thanks to its balanced combination of strength, ductility and weldability. With a typical yield strength of around 250 MPa, it provides good structural integrity whilst remaining easy to machine and work. A36 steel also exhibits good formability and moderate toughness, making it suitable for both structural and fabrication applications. Mild steel is commonly used in construction, manufacturing and general fabrication where it can be found in structural members, bridges, frames, brackets and various industrial components. Its versatility and cost-effectiveness make it a popular choice for projects requiring a durable and workable material.

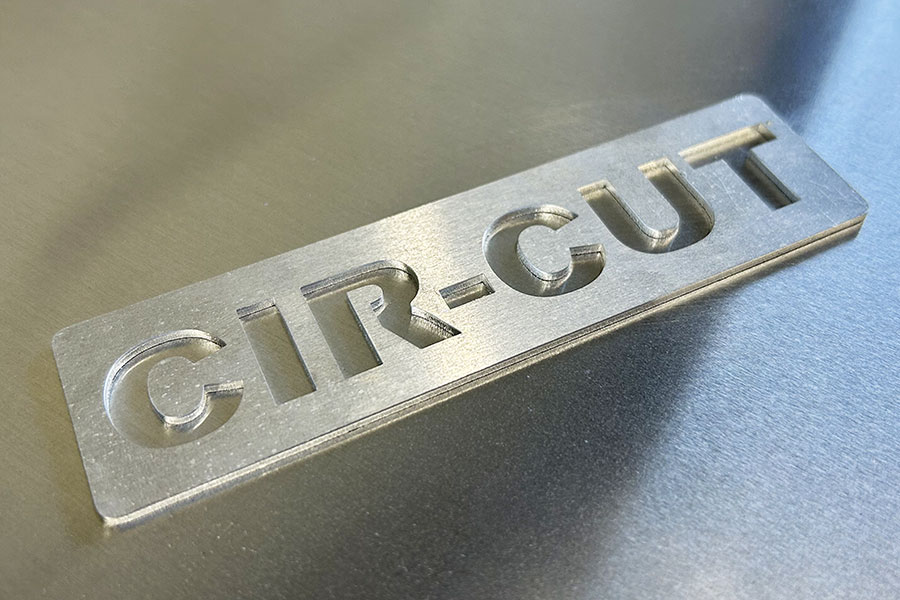

Stainless Steel (304-2B)

- 0.9mm

- 1.5mm

- 3mm

Stainless steel 304 is the most commonly used stainless steel alloy, valued for its excellent corrosion resistance and workability. It is non-magnetic in its annealed state and has lower thermal and electrical conductivity compared to carbon steel. Commonly used in kitchen equipment, food processing and architectural applications due to its good performance in outdoor and mildly corrosive environments.

Material Finishing

We ensure that any large burs are removed from your parts before we send them out, however without complete post-process finishing you may need to further finish them. The simplest solution is sanding, but this will alter the finish of the material so aesthetically this is up to you and your project requirements.

- Powder coating: we offer powder coating on your laser cut pieces. This will increase the lead time and the additional cost will be calculated at the quoting stage.

- Sanding: we can do the sanding step for you, if you aren’t too concerned about the final look of the surface. Just simply select this at the quoting process!

Tips on designing parts for laser cutting

Holes

- As a rule of thumb, holes should be no smaller than the thickness of the material

- Be mindful of hole placement if you intend to add any bending to your pieces. You don’t want to distort your components during manufacturing.

- If you are planning on powder-coating any pieces, note that any hole geometry will need additional tolerance to account for the coating (generally + ~0.5mm on the diameter).

Text

- When it comes to lettering – the bigger the text the better the result. As a rough guide, ensure that your text height is greater than 10x the material thickness.

- Make sure your letters have bridges on any internal pieces that could fall out during cutting. These bridges should be a minimum of 1.5mm.

Upload & Pay

Cir-cut’s upload function accepts DXF or DWG files with an instant quoting system, allowing you to upload and pay for your designs to be processed and manufactured ASAP. No emails and consulting needed.

You can log in to an existing account, or checkout as a guest – either way, you can trust that your files are secure and that you will always retain the intellectual property and privacy of your designs.

Supported Files: DXF, DWG

Support Services

If you don’t have the ability to design in CAD, or are having trouble with your files, flick us an email and we can help bring your concept to life. Our team has design and manufacturing experience and are happy to help you get your job done (additional fees may apply).

Cir-cut is Australia’s easiest laser cutting service boasting a streamlined ordering process, ensuring you receive your own quality parts fast.

You can upload your accepted design file, receive an instant quote, pay online, then receive your laser cut pieces in a single smooth transaction – no mucking around with emails and a lengthy quoting process.

We know that some laser cutting services within Australia don’t manufacture your pieces locally – Cir-Cut’s home is right on the Sunshine Coast in QLD and is family owned and operated.

Our aim is to make laser cutting services accessible for everyone, from fabricators and manufacturers to hobbyists and backyard tinkerers. We want it to be affordable and simple so that all your projects can have home-grown, quality results.

We understand that sometimes you just need a quick patch job or want to test out the fit of a component, so rather than purchasing multiple pieces that will gather dust in the shed, we have NO minimum order quantity. Trust us, we’ve been there!

Frequently Asked Questions

Simply email us at circut@cirlock.com.au and we can work with you and provide support.

Yes – we offer powder coating and basic sanding, depending on your requirements.

Yes – we are located in Kunda Park on the Sunshine Coast. Please ensure you reach out to us before you swing by so we can make sure your pieces are ready to go!

Please reach out to us if there is another material that you need for a project, that isn’t listed online. We have the capacity to source materials to make your project happen!

Where possible, we will use an Overnight service. This will depend on the final weights of your order and where in the country you live, otherwise you should see your pieces within a few days from shipping – NT and WA may take up to ~7 days for large orders.

We do. Our team has CAD experience and can help bring your idea to life. Please note this will incur an additional cost and is best to email us for a free chat first.